A new pilot project for will provide an answer. After ten years of research, Air Products is ready for live testing of its membrane-based cleaning technology. In December, a limited amount of membrane modules will be installed in the chimney at Returkraft.

Rune Damsgaard, Sales Director at Air Products, is looking forward to gaining valuable experience through the pilot.

“We will need to figure out how to organize and optimize the cleaning process. We also need to test how to arrange the membranes, and how to control other parameters,” says Damsgaard.

SCALABLE

Damsgaard believes Air Products’ membrane technology has several advantages compared to other CO2 cleaning methods on the market.

“It is flexible, it handles capacity adjustment well, and it tolerates variables in the gas flow. Moreover, our process involves no toxic components,” says Damsgaard and adds:

“The results from the pilot at Returkraft will provide answers as to how a full-scale treatment plant can be realized and at what price”.

IMPORTANT ANSWERS

Returkraft has been working on plans for CO2 purification for several years. The pilot project is estimated to cost NOK 8.5 million. Half of the cost is picked up by CLIMIT, which is the national program for research, development and demonstration of technology for CO2 management. Returkraft and Air Products cover the rest.

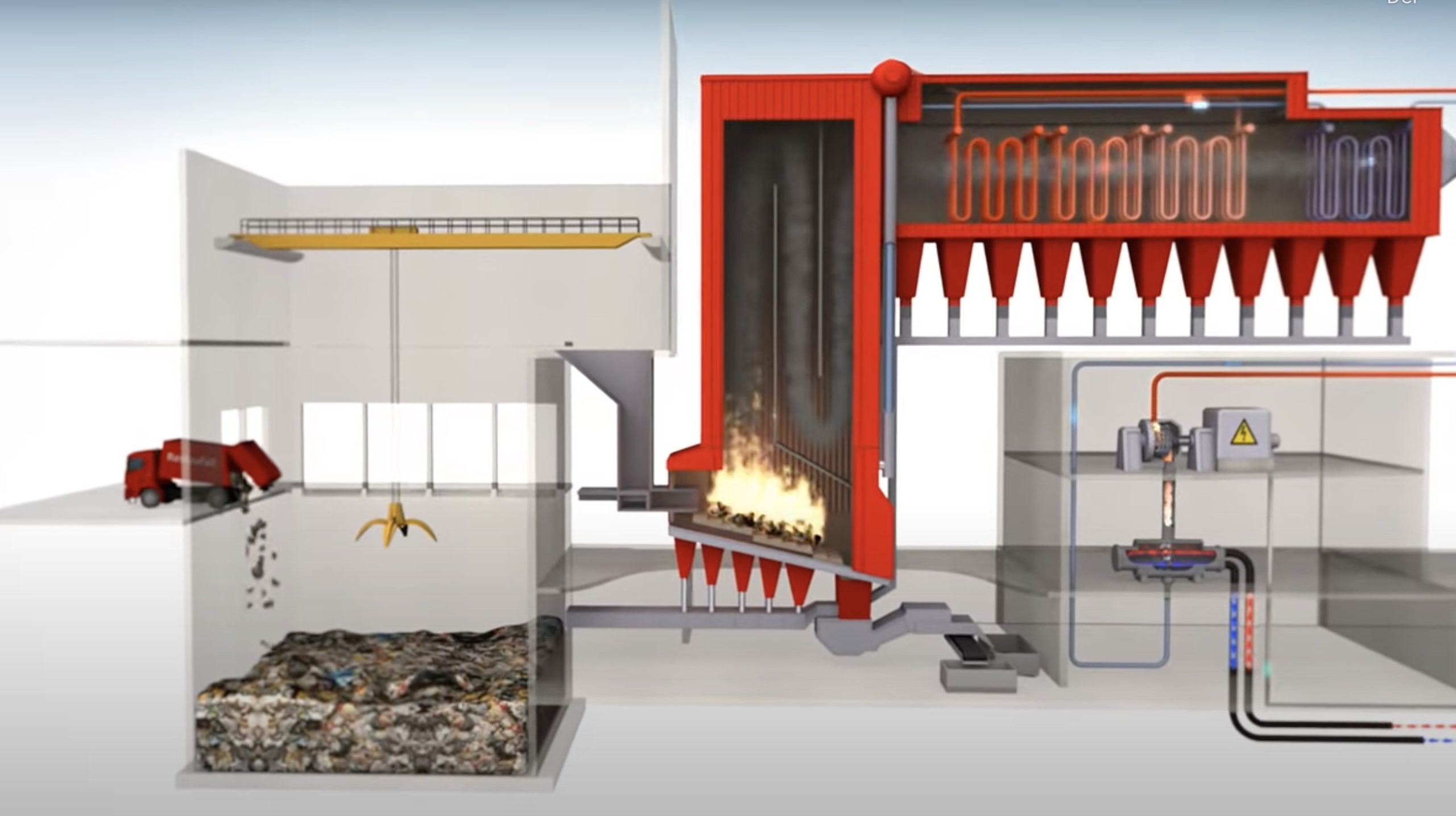

The idea is that the CO2 captured by Returkraft and other industrial companies is to be transported by ship to the North Sea and stored in reservoirs under the seabed. Lars Erik Harv, acting Managing Director of Returkraft, says there is great uncertainty about what the price tag for full-scale cleaning and storage will be.

“We hope to calculate the price of capture and storage in 2025 or 2026. If a decision to start construction is made the following year, we can have the facility ready in 2030,” says Harv to fvn.no.

CO2 purification is an energy-intensive process. For Returkraft, the ultimate solution will be to use surplus energy from its heating plant in the cleaning process. In nine out of twelve months, the plant generates more heat energy than is needed to meet demand.