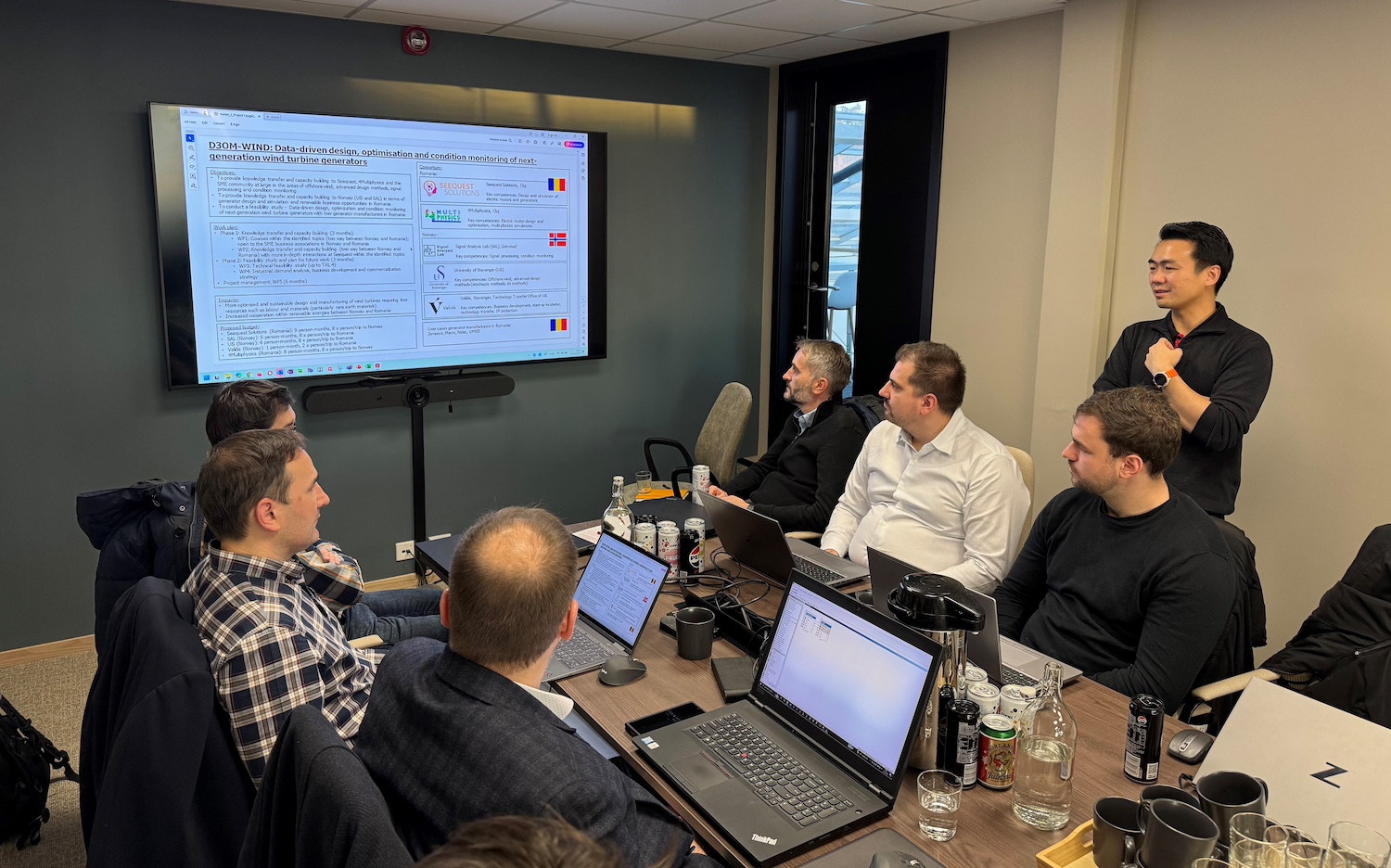

A recent seminar in Kristiansand, featuring expert engineers from 4Multiphysics and Seequest Solutions in Romania, provided a fascinating introduction to the development of powertrains in the battery electric vehicle industry.

The focus was on creating eco-friendly, reliable, and cost-efficient motor designs that could significantly enhance performance and efficiency in offshore applications.

The seminar highlighted that electric motors and generators which produce electric energy, are fundamentally based on the same technology. The seminar covered various important design parameters and challenges in achieving robust designs while emphasizing energy and cost-efficient solutions.

Participants were introduced to the different electric motors and gear designs currently used. Cooling and temperature control principles were also presented. These were evaluated in terms of efficiency and cost, with discussions on the potential for design optimization using state-of-the-art simulation tools and expertise.

The importance of material selection, lubrication, design tolerances, and vibration control for quality control and condition monitoring was thoroughly explored. Additionally, the seminar addressed how geopolitical factors influence the development of electric powertrains, particularly in reducing dependence on critical mineral resources like rare earth elements.

Development of electric powertrains and generators still holds significant potential for improvement to meet service life expectations, especially under harsh offshore conditions with high dynamic and cyclic loading, vibrations, wear, and corrosion. The offshore wind industry faces major challenges in these areas, and much more effort is needed to qualify their technology for real offshore exposure.

“This topic is also crucial for the green transition, addressing supply chain issues of critical minerals. The seminar clearly demonstrated that achieving these goals requires a multidisciplinary effort involving highly qualified mechanical engineering, tribology, metallurgical/material science, thermodynamics, fluid mechanics, and heat transfer, combined with advanced electrical engineering. Proving to be interesting challenges for our industry and technology experts to dive into,” said Christian B. von der Ohe, RD&I Manager at GCE NODE.

GCE NODE would like to extend it gratitude to Geir Kulia and Signal Analysis Lab for initiating and organizing this seminar as part of their D3OM-WIND project for condition monitoring of next-generation wind turbine generators.

Both Kulia and von der Ohe are available if you are interested in further exploring the possibilities presented by this project.