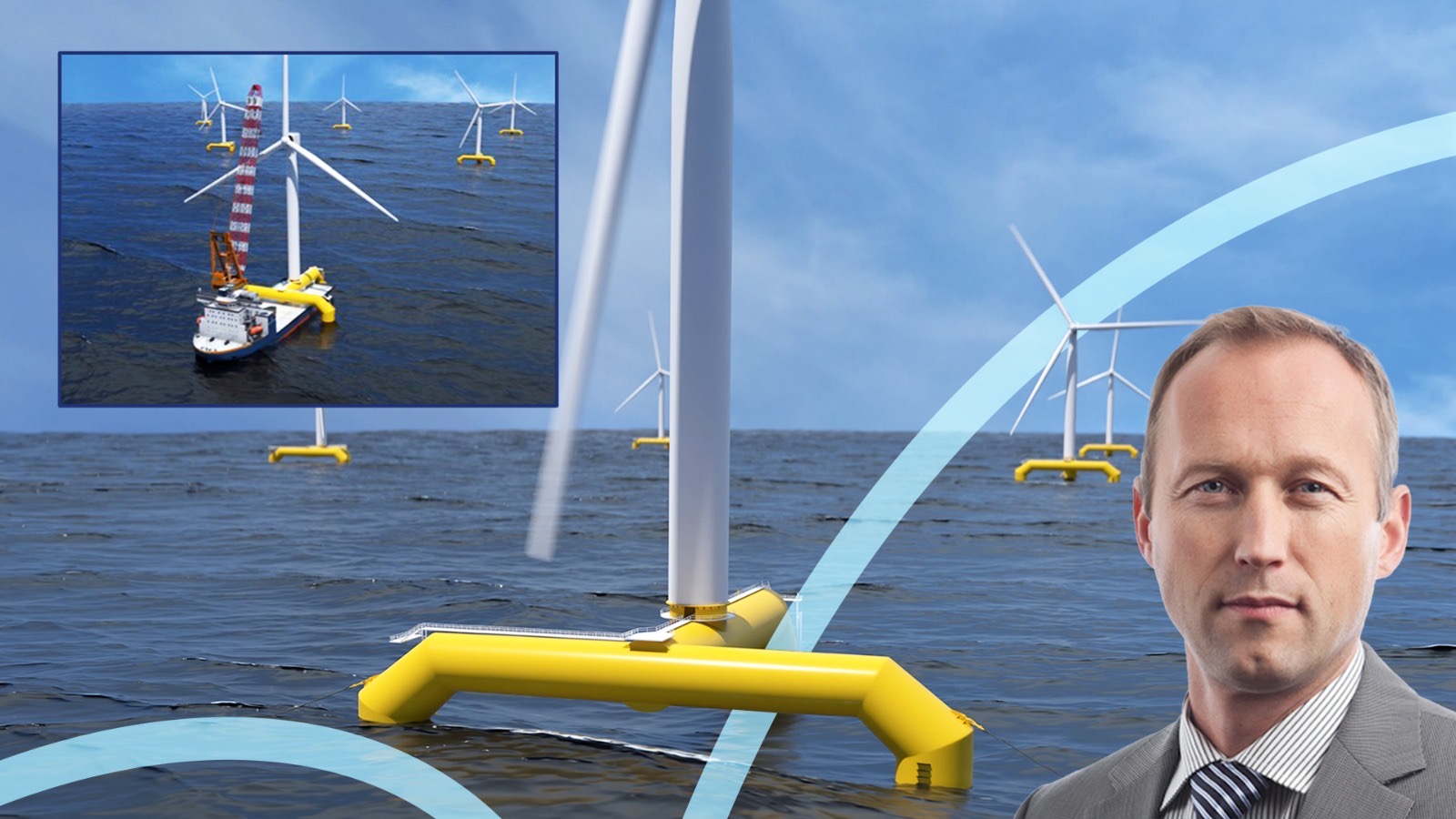

As the world looks to expand offshore wind capacity to meet ambitious targets, Ocean Ventus is launching a new end-to-end solution to deliver cost-competitive power from floating wind.

Foundations remain a bottleneck for the build-out of large-scale floating wind farms. Existing floating wind foundations are heavy, complicated, difficult to produce, and challenged by constrained supply chain capacity.

“Ocean Ventus offers an end-to-end solution at low-cost for the floating wind market, from foundation production to transportation, assembly, and maintenance. The company’s design, which saves up to 40% on steel costs and CO2 emissions, has now received Approval in Principle from DNV,” says Ingvar Apeland, CEO of Ocean Ventus.

According to Ocean Ventus, their floater can be mass manufactured using similar methods employed for monopile production, while modular construction allows for simplified transport on low-cost vessels. Assembly utilizes two purpose-built barges that can complete 50 floating units per location annually, minimizing use of quay space. Finally, the foundation is designed to work seamlessly with a patent-pending service vessel, enabling turbine maintenance offshore and eliminating the need to tow to shore.

To further reduce costs, Ocean Ventus plans to establish dedicated large-scale production facilities and is exploring the potential for a first factory in Norway. The factory will target production up to 50 structures per year and ramp up in 2028 for delivery to license rounds in key markets.

“Foundations are a key challenge to making floating wind cost competitive, and we believe that Ocean Ventus is uniquely positioned to address this challenge,” said Halvor Ribe, Chair of Ocean Ventus AS. “Our simple design, modular components, and industrialized process allow for serial production and significant cost savings. We are excited to bring this technology to market and support the growth of offshore wind in Norway and worldwide.”