Mandals’ signature lay flat hoses are low weight and easy to use and re-use. Furthermore, the hoses can withstand all kinds of stresses in the form of pressure, tension, temperature and other wear.

Some time ago, Fenner Mandals received a phone call from the other side of the globe.

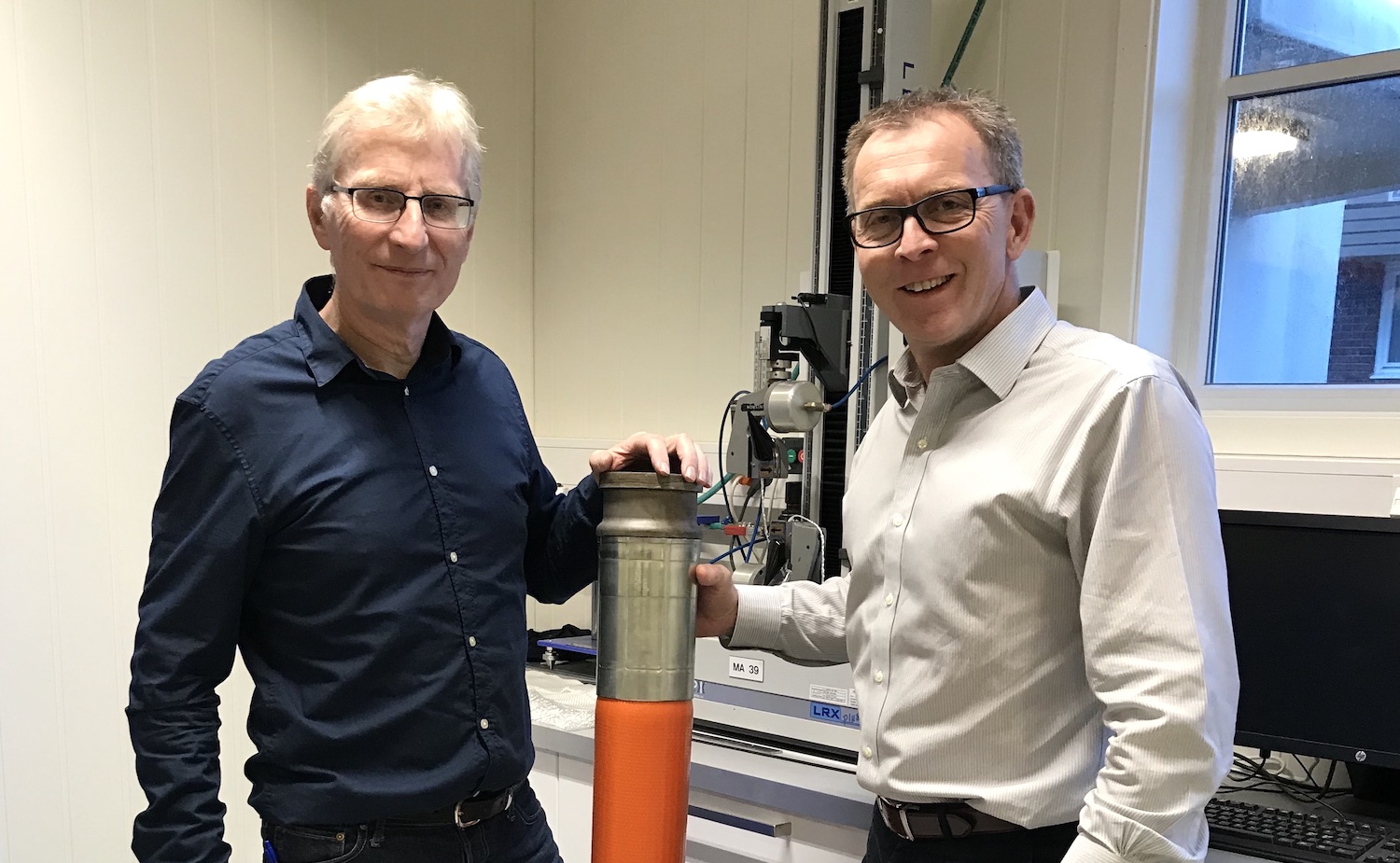

“The Indian National Institute for Ocean Technology had been made aware of the super-duper hose we produce in Mandal and asked if it could be used for subsea mining,” says Knut Mjåland, CEO of Fenner Mandals.

The company soon entered into a comprehensive R&D program with the Indian institute to develop a mortar hose able to pump up slurry from the seabed at 1000 meters depth. The hose has been thoroughly tested in Mandal, where it has been pulled with 25 tons from each end, while pumping at high pressure. The result: A hose that can withstand more than 200 bar.

Phase 2 will be a full-scale test at 6000 meters, scheduled for the spring of 2020.

“Endurance, chemical resistance and pull are parameters embedded in our design. The hoses are monsters, especially manufactured for this sole purpose. You won’t find anything similar anywhere in the world,” says Mjåland.

He emphasizes that the technology can be applied in other industries.

“Lay flat hoses produced for seabed mining can, of course, be utilized in other industries like oil and gas and pipe rehabilitation,” says Mjåland.

For MacGregor Norway, subsea mining is an emerging market, which CEO Høye Høyesen characterize as “somewhat interesting”.

“We have delivered cranes and lifting equipment to the world’s first seabed mining ship, which is still not operational. Today, we are involved in projects to develop mooring solutions for similar ships,” says Høyesen.

“Valuable minerals have been discovered in the seabed. When the technology has matured, I am convinced that subsea mining will be a business area. We do, however, need to develop good, cost-efficient solutions. And there is still a lot of skepticism to excavating minerals from the seabed, with the environmental issues this arises,” says Høyesen.

National Oilwell Varco has delivered equipment to excavate diamonds from the seabed. NOV is extending the reach and utilization of its active heave compensated subsea cranes to go deeper without sacrificing the crane safe working load. This enables salvage companies to reach depths that were previously inaccessible. It is done by extending or replacing the heavy steel wire rope with fiber rope. The technology will also open up for other activities that have been impossible due to limitations in existing offshore hoisting systems.

“This is not top priority for us right now, but there is certainly lots of technology and competence that could be transferred from oil and gas to seabed mining,” says Frode Jensen, Managing Director at NOV Norway.

READ MORE:

https://gcenodeno.tempurl.host/news/oil-and-gas-competence-transfers-to-offshore-wind/

https://gcenodeno.tempurl.host/news/aquaculture-has-great-potential/

https://gcenodeno.tempurl.host/news/committed-to-geothermal-energy/

https://gcenodeno.tempurl.host/opinions/transfer-of-technology-and-competence/