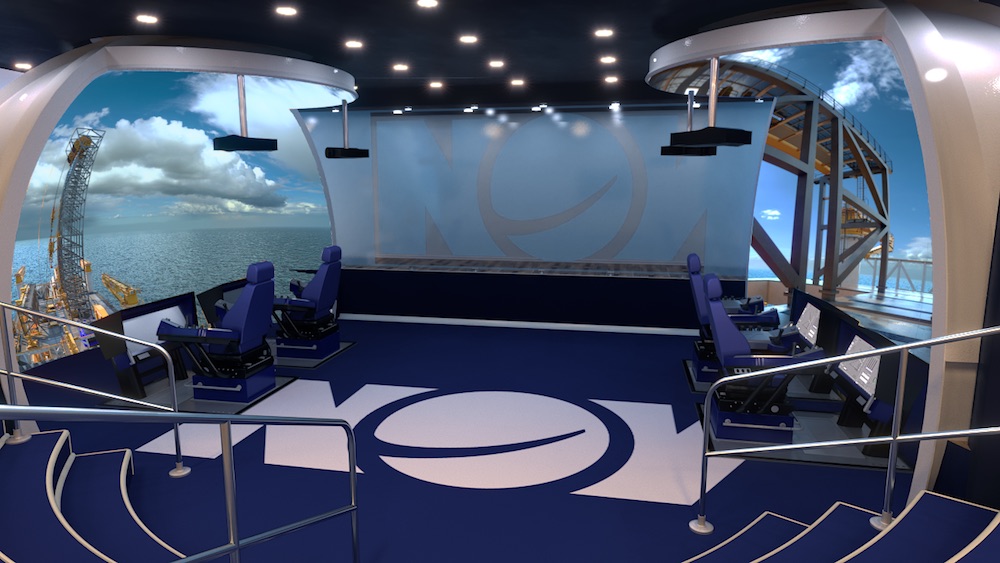

“Our goal is to remove the driller from the drill floor. State-of-the-art simulator technology enables us to provide the driller with live 3D images from the drill floor. It will be like being on the drill floor, but in reality the driller will be somewhere else on the rig – in a much safer area”, says Stig Trydal, Director Rig Offshore Controls at National Oilwell Varco.

Funding for the project was recently provided by the Demo2000-program. The program supports projects that aim to reduce cost and improve safety. ‘Remote drill floor operation’ could do both.

”We will install our new technology on a Maersk Drilling rig. Maersk, with their close to fully automated rigs, is a perfect partner for us in this projects”, says Trydal.

REVOLUTIONIZING WATER INJECTION

The other NOV project that has also received funding from the Research Council of Norway, is the building and testing of a full scale prototype system for subsea production of sulfate free or low salinity water.

“This is the last leg of an innovation project that includes a unique technology and several global patents. We will build a full-scale prototype designed to operate at up to a depth of 3000 meters”, says Helge Lunde, Managing Director at NOV Completion & Production Solutions – Seabox.

The SWIT™ technology enables production and injection of ‘tailor made’ seawater to any desired specification, including sulfate free and low salinity water directly from the seabed. The technology allows for decoupling production and injection operations and is inherently a flexible, safe and environmental friendly solution. The technology enables a step change in reservoir and asset management, reducing cost, accelerating production and optimizing recovery.